History: Motueka fruit growers’ syndicate

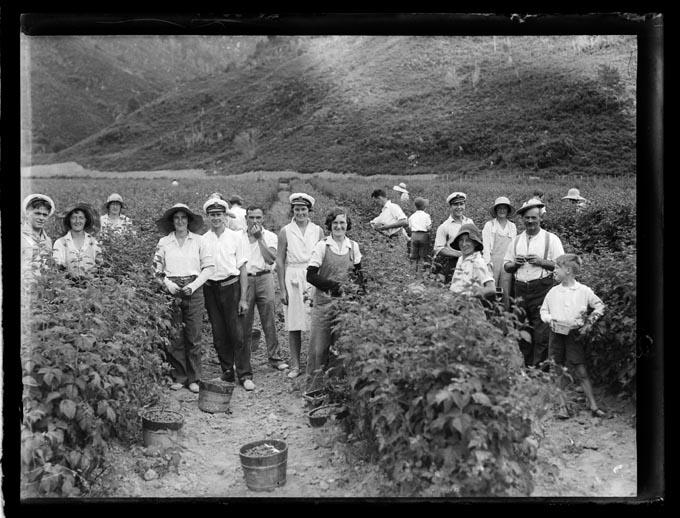

Raspberry picking. Photo: Nelson Provincial Museum, Kingsford Collection: 161680.

BY ROBYN PARKES

The suitability of the soil in Motueka, Riwaka and surrounding areas for growing small fruits such as raspberries, currants, gooseberries and other berry fruit had been made evident and landowners extended their acreage to get bigger crops.

However, with the increase in fruit supplies came the difficulty of selling it at what was considered to be an acceptable price for the growers.

After a number of months of discussion, it was decided to secure a plant to pulp the fruit, so arrangements were made to rent the machinery and buildings belonging to F. W. Thorp.

Subsequently, the Motueka Fruit Growers Syndicate established a much-needed industry on a small scale at the Burton Fruit Canning Works under the management of Robert Dunkley.

The initiative was, at first, looked upon with some distrust by some growers, but there was hope that in time all would support it as being beneficial.

In all, sixteen people were employed at the pulping factory with another handful of people working in a voluntary capacity.

The operations of the pulping began with casks containing ripe raspberries, currants, etc., being placed on a platform where, after inspection, it was weighed with the weight recorded and a copy given to the grower, showing gross and tare quantities.

The fruit then emptied from barrows into the shoot and ran down into copper jacket pans. After being boiled for a specified time, during which time all scum was removed and thrown away, the pulp was tipped into receivers and then poured into the tins, which, when filled, were capped by soldering them on. The tins are placed in the trays, hermetically sealed, and lifted by means of a pulley into the pans. Once the pans were filled with tins, they were subjected to a steaming process creating the vacuum within. Once this was finished the filled tins were removed to the testing room, remaining there for around six days to identify any bad ones. The final process was to label, lacquer and box the tins ready for market.

The tins were made in a building close to the factory, cut out by guillotine and notched by machine, eliminating the need to notch them by hand.

A patent folder was used for folding bodies of square tins and also one for tops and bottoms. Other machines involved in the tin-making process were several double crimpers, rollers and a wing press. Already there were plans to extend the operations for the following year with a bigger building instead of the current position of several buildings used which was making it harder for the manager to oversee the work.

By January 1902, over 60 tons of fruit had been canned with the pulp considered to be of absolute pure quality and of a very rich colour. The projected target for the following years was the have the capacity to handle around 1000 tons annually.

In looking to the future, the New Zealand Government agreed to send a ton of raspberry pulp overseas to test the English market.

With this success, the founders of the syndicate were congratulated for their forethought and hard work.